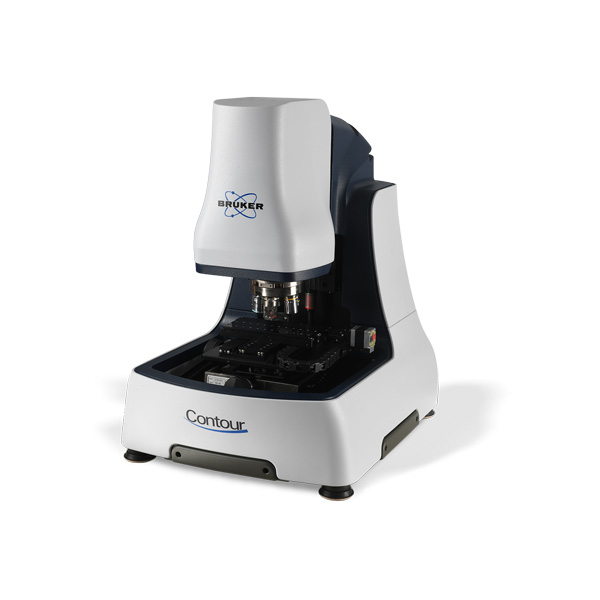

Flexible Benchtop Topography Metrology Solution

The optical profiler provides the perfect combination of advanced characterization capabilities, optional custom accessories, and ease of use. It is the fastest, most accurate, and most repeatable non-contact 3D surface metrology system in its class.

The metrology system occupies a small area, adopts a larger field of view, a digital camera and a new electric XY table, and has excellent 2D/3D high-resolution measurement capabilities.

Unparalleled Z-axis resolution and accuracy, with all the industry-proven benefits of Bruker's proprietary White Light Interferometry (WLI) technology, without the limitations of traditional confocal microscopes and comparable common optical profilers.

Best-in-Class Metrology Technology

Relying on more than 40 years of WLI's independent innovation achievements, the optical profiler can meet the low noise, high speed, accuracy and precision required for quantitative metrology.

Using a variety of objectives and pattern recognition, features can be tracked across multiple fields of view with sub-nanometer vertical resolution, providing size-independent results for quality control and process monitoring applications across multiple industries.

Stable performance on all surface conditions from 0.05% to 100% reflectance.

New hardware features include an innovative stage design for larger tiling, lower noise, larger field of view and higher lateral resolution.

Widest range of application analysis capabilities

Utilizing the powerful VisionXpress and Vision64 user interfaces, it offers thousands of custom analyzes to improve laboratory and plant efficiency.

Bruker's new Universal Scanning Interferometry (USI) measurement mode provides fully automatic, self-aware surface texture, optimized signal processing, while performing the most accurate and realistic calculations for the analyzed surface topography.

The system features a new camera with an expanded field of view, combined with the flexibility of a new motorized XY stage, for increased flexibility and efficiency when handling a wide variety of samples and parts.

The perfect combination of software and hardware achieves excellent optical performance, surpassing similar measurement technologies in an all-round way.